Sekundärrohstoffe als Basis für die Herstellung von Qualitäts-Neuprodukten

Dass Kunststoff-Abfälle wieder zu jenen Produkten werden können, welche sie bereits einmal waren, ist gleichermaßen unsere Grundidee wie unser größtes Ziel. Dazu leisten wir mit der Verwertung von Polyethylen-Abfällen und deren Recycling zu hochwertigen Rezyklaten einen wertvollen Beitrag. Rezyklate sind wiederverwertete Kunststoffe aus sogenannten Post Consumer-Abfällen. Dies sind Kunststoffe, welche bereits mindestens einmal nach Ihrem Gebrauch im Rahmen eines Haushalts- oder Gewerbeabfalls entsorgt wurden. Die Erzeugung von Sekundärrohstoffen bzw. Rezyklaten wird mithilfe eines aus mehreren Schritten bestehenden Produktionsprozesses durchgeführt, wobei der Prozessschritt des Heiß- oder Kaltwaschens eine wichtige Unterscheidung zwischen der Herstellung von Rezyklaten (mit Waschvorgang heiß oder kalt) und Regranulaten (ohne Waschvorgang) darstellt.

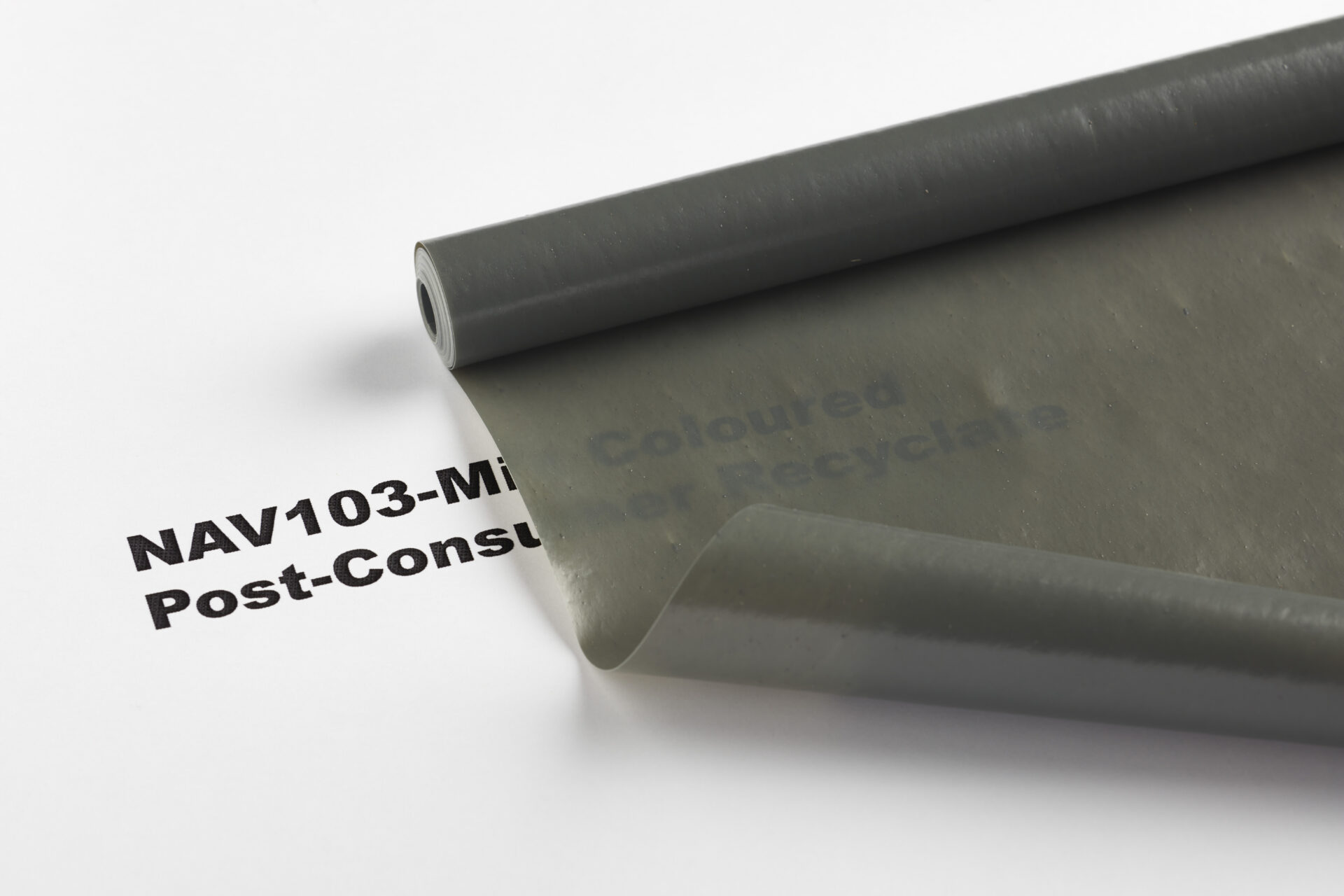

Die von uns erzeugten Rezyklate erlauben es unseren Kunden, in den allermeisten Fällen wieder dieselben oder ähnliche Produkte herzustellen, die sie vor der Entsorgung bereits einmal waren. Das schließt den tatsächlichen Recyclingkreis.